Services

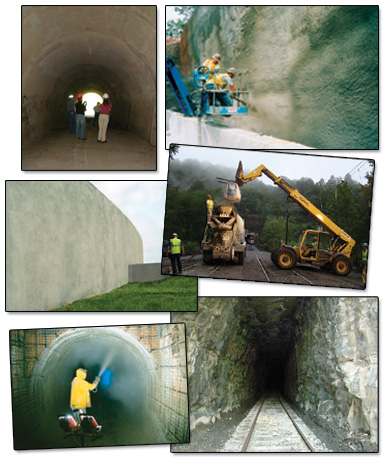

Restore Deteriorated Concrete Safely & Efficiently

Thousands of deteriorating and outdated storm drains and sewer pipes below ground cause millions of dollars in damage to businesses throughout America. Protect your investment with a low cost, no obligation inspection.

Save Time, Labor and Material

Due to rapid application, Gunite/Shotcrete requires no forms to be built or removed. Even to rehabilitate projects such as tunnel bridges, dams, ditch linings, foundation walls, containment structures and levies.

FENTON routinely saves as much as 20% in below grade construction time when compared to poured concrete. Our lightweight, portable equipment goes where needed. No delays in getting to the job site means less lost time. Unlike poured concrete, Gunite/Shotcrete cures rapidly. Time is not wasted between pours. Structural requirements are met without delay, allowing other phases of construction work to proceed ahead of schedule.

Trust Our Experience

Quality control is the foundation of our continued success and is highly dependent on the skill of our nozzlemen and finishers. Fentonís certified personnel have the experience and skill needed to tackle tough challenges with critical precision. And restore any structure to its original lines and elevations.

Proper preparation of treatment areas is also crucial. Our dedication to quality ensures that all deteriorated concrete is removed properly and reinforcing elements are placed correctly to allow for proper bonding. This establishes optimum Gunite/Shotcrete performance and endurance.

Rely On Our Technical Expertise

Due to rapid application, even costly forms are eliminated to rehabilitate projects such as tunnels bridges, dams, ditch linings, foundation walls, containment structures, levies, etc.

- Shotcrete and Dry Mix Gunite

- Polyurethane and Epoxy Crack Injection

- Acid-Proof Linings and Membranes

- High-Quality Concrete Restoration

- Waterproofing

- Waterproof Coatings

- Cementious Pressure Grout

- Sanitary Sewer Manhole Linings

Would you like Fenton to hold your project up? Or hold it down?

We can do both! Whatever you need for ground support, Fenton's has the answer.

Micropiles

Micropiles are the fastest growing deep foundation application, providing high bearing capacity in tight quarters. They offer the same stability as driven steel piles and ease of installations in areas with difficult access. Micropile drilling methods generate minimal disturbance to adjacent structures, which makes them an excellent choice for underpinning. Because of their smaller size, a wide variety of drilling techniques can be utilized more economically Ė whether the job calls for a retrofitted foundation inside an existing structure or building a new one in a minimal space.

Tie Backs

Tieback anchors are effective in braced deep excavation projects and can be installed using common rotary drilling equipment. The choice of the drilling method depends on the siteís soil and rock conditions. Tiebacks are designed to create the highest stiffness possible in order to keep wall movement and ground settlement to a minimum.

Shotcrete Shoring

Fenton can provide a combination of shoring, excavation and Shotcrete services that can create critical time and cost savings for our clients. Our shoring support systems have helped countless companies complete their projects on time, on budget and more safely during building renovation, excavation, and new construction using a variety of project specific designs.

Compaction Grout

As geotechnical construction specialists, Fenton has used compaction grouting for ____ years to increase the density of soft or loose soils and improve the ground underneath settling structures. By using small injection ports, compaction grouting can be implemented with minimal disruption to building use. This technique can also be used to fill rock cracks, stabilize sinkholes, provide excavation support, stop the flow of liquids, and re-level roads, bridges and other existing structures.

Shotcrete Walls

Although relatively new in the United States, using Shotcrete to form walls has been used in other countries for years. These walls consist of a polystyrene core sandwiched between layers of wire mesh or rebar. First, a wire frame is built in the shape of exterior walls. Conduit and pipe are installed between the poly panels and the wire mesh. Then the entire structure is sprayed with Shotcrete. The result: a reinforced wall with built-in insulation.

Soil Nailing

Soil nailing technology creates retaining walls that reinforce the soil mass without excavating the soil behind the wall. Soil nails, normally steel reinforcing bars, are usually installed into pre-drilled holes, then grouted into place. However, they can be drilled and grouted simultaneously. Soil nailing can provide stability for cut slopes, landslides and many deep excavation applications.

Soil Anchor Walls

Fentonís years of experience and innovation helps provide creative soil anchor solutions for todayís most challenging projects. Ranging from 50 to 200 tons of working load and going hundreds of feet deep, rock and soil anchors have proven to be a cost-effective alternative to conventional retaining walls and internally braced systems. For dam stability, our anchors have achieved loads over 1,000 tons.

Chemical Grout

Fenton uses the most advanced polyurethane and epoxy product technology available to help fill voids in the soil, while meeting the strictest specifications for environmental safety. One big advantage of this process is that soils can be stabilized without any major changes to the soil volume and structure, thus making it less disruptive than many other methods. Designed to stop water leaks, a typical use may include crack or joint repair in concrete structures such as foundation walls, tunnels, dams, and large diameter pipes.

Cellular Concrete

This lightweight concrete isnít as strong as ordinary concrete, but it withstands the elements just as well. It may provide an excellent alternative because of certain advantages: smaller foundation requirements; better fire resistance; less need for structural steel reinforcement; self-insulating. Let the experts at Fenton help you determine the right material for your particular project.

Pressure Grout

Underpinning

Jacked Piers